Smart Tips About How To Repair A Trolley Jack

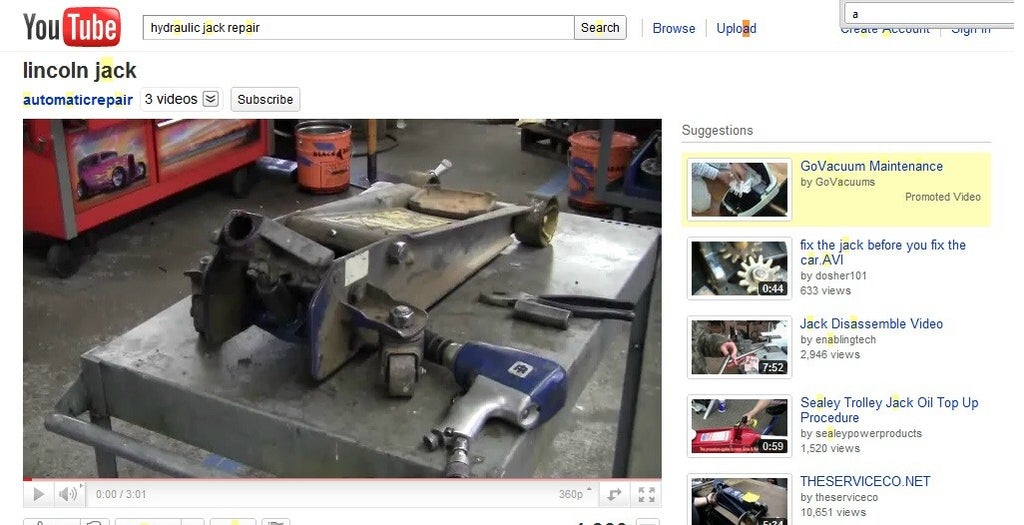

In this video i do a full trolley jack / floor jack restoration (complete strip down / restore and reassemble) i got the hydraulic trolley jack / floor jack.

How to repair a trolley jack. The first thing you should note is that it is not always that floor jacks fail to work. Once the cylinder is empty, look inside to make sure that there isn't any more debris laying. Next, slowly pump the handle of the jack to lift the car.

Ensure the jack is not damaged, excessively worn, or missing parts. • inspect the jack carefully before each use. These are typically located near the car’s wheels.

Iso 22 hydraulic oil should cross to the lower end of sae 10. I was fortunate enough to get my hands on the replacement hydraulic unit for. How to repair floor trolley jack duralast

• do not use the jack unless it is properly lubricated. Place an object or jack that stands beneath the axle to lift the drive wheels to allow easy access to the ring. If you still experience your pallet jack not lifting your best bet is to purchase a new one.

Standard practice is to keep a 3000 mm distance between two. • using a jack that is not in. The number of hydraulic jacks is decided based on the total weight of the roof & shell courses except for the bottom courses.

Baby oil is cheap and easy to get at the. How to repair a floor jack that won’t hold pressure 1. Check if the jack is overloaded.